The PCT Pressure Cooker Highly Accelerated Aging Test Chamber is widely used to test the durability and reliability of materials, coatings, and electronic components. It simulates high-pressure and high-temperature conditions, making it ideal for applications in the automotive, aerospace, electronics, and construction industries. Typical uses include evaluating the corrosion resistance of metal coatings, the moisture tolerance of electronic components, the strength of adhesives and sealants, and the aging effects on materials like rubber and plastic under harsh conditions.

Advantages of PCT Aging Chamber:

Realistic Environmental Simulation:

The chamber simulates extreme conditions of high temperature and pressure, closely mimicking the real-world environmental challenges materials face, leading to more accurate testing outcomes.

Accelerated Aging:

PCT chambers reduce the time needed to observe long-term material degradation, providing quicker results on the durability and reliability of the test samples under extreme stress conditions.

Enhanced Safety Features:

Automated Protection: Features like automatic water refilling, double overheat protection, and pressure safety valves ensure safety during operation, preventing overheating, scalding, and overpressure accidents.

Integrated Safety Devices:

The machine automatically shuts down if the chamber is not sealed properly, safeguarding operators and equipment.

High Testing Precision:

Digital Control and Monitoring: The chamber is equipped with digital displays and programmable controllers to regulate temperature, pressure, and time with high accuracy. This ensures consistent, reliable testing and data collection.

Superior Steam Quality:

The system includes an automatic steam discharge feature that removes non-saturated steam, ensuring that only the highest quality saturated steam is used, thus improving the accuracy and consistency of the test conditions.

Durable Design:

High-quality Materials: The chamber’s inner box is mirror-polished for easy cleaning and preventing contamination during tests, while the silicone gasket ensures a tight seal and long operational life.

| Model | HAST - 25 | HAST - 35 | HAST - 45 | HAST - 55 | HAST - 65 | ||||

| Internal Dimension ΦxD (mm) | 300x250 | 350x450 | 450x550 | 550x650 | 650x750 | ||||

| External Dimension ΦxD (mm) | 850x1300x900 | 900x1350x900 | 1000x1480x1000 | 1150x1650x1200 | 1300x1800x1350 | ||||

| Steam Temperature Range | Steam Temperature Range: 100℃~135℃, (143℃ is optional) | ||||||||

| Relative Pressure/ Absolute Pressure | Relative pressure: display values indicated on the pressure gauge Absolute pressure: pressure gauge value adds 100 Kpa (The actual value in the inner box) | ||||||||

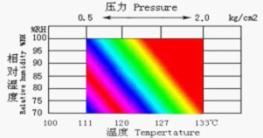

| Comparison Table of Temperature, Humidity , Pressure |  |

||||||||

| Steam Humidity | 70~100%R.H. steam humidity adjustable | ||||||||

| Steam Pressure(Absolute Pressure) | 101.3Kpa +0.0Kg/cm2 ~ 2.0Kg/cm2 ; (3.0Kg/cm2 is special standard) | ||||||||

| Recursive Device | Steam in forced-circulation | ||||||||

| Safety Protective Device | Water short storage protect, over pressure protect.(have automatically/manual water replenishing, automatically discharge pressure function ) | ||||||||

| Accessories | Two layers stainless steel plate | ||||||||

| Equipment Capacity(L) | 17 | 43 | 87 | 155 | 250 | ||||

| Power | AC 220V(±10%), 1∮ 3 Lines ,50/60HZ; AC 380 V(±10%) ,3∮ 5 Lines,50/60HZ | ||||||||

| Model | PCT - 25 | PCT - 35 | PCT - 45 | PCT - 55 | PCT - 65 | |

| Internal Dimension Φ×D (mm) | 300×250 | 350×450 | 450×550 | 550×650 | 650×750 | |

| External Dimension Φ×D (mm) | 750×1200×800 | 800×1250×800 | 900×1380×900 | 1050×1550×1100 | 1200×1700×1250 | |

| Temperature Range of Saturated Steam (Operating temperature) | (Temperature Range of Saturated Steam:100℃~135℃) , Temperature Range: 120℃,100Kpa/ 133℃ 200 Kpa;(143℃ is special order) | |||||

| Relative Pressure/ Absolute Pressure | Relative pressure: display values indicated on the pressure gauge Absolute pressure: Value that add 100 Kpa based on display values indicated on the pressure gauge (The actual value in the inner box) | |||||

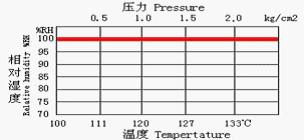

| · Comparison Table of Temperature, Humidity , Pressure of Saturated Steam |  |

|||||

| Humidity of Saturated Steam | 100%RH saturation steam humidity | |||||

| Steam Pressure(Absolute Pressure) | 101.3Kpa +0.0Kg/cm2 ~ 2.0Kg/cm2 ; (3.0Kg/cm2 is special standard) | |||||

| Recursive Device | Steam Natural convection circulation | |||||

| Safety Protective Devise | Water short storage protect, over pressure protect.(have automatically/manual water replenishing, automatically discharge pressure function ) | |||||

| Accessories | Two layers stainless steel plate | |||||

| Equipment Capacity(L) | 17 | 43 | 87 | 155 | 250 | |

| Powder | AC 220V(±10%), 1∮ 3 Lines ,50/60HZ ; | |||||